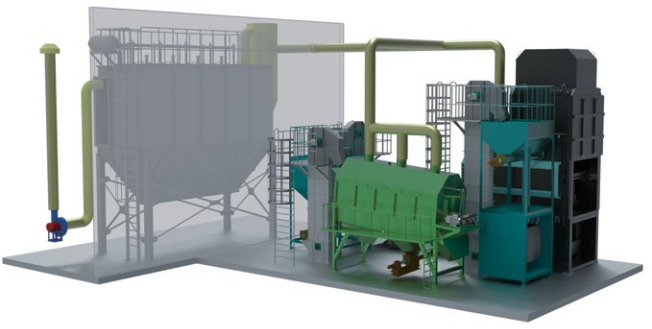

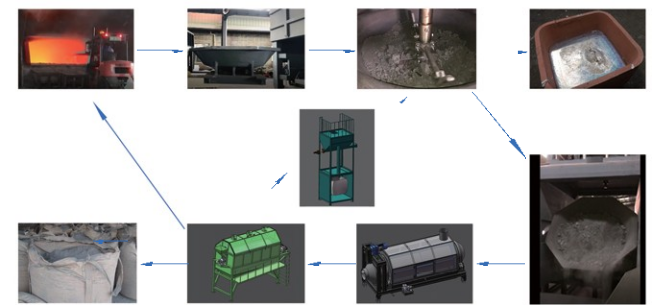

HT500 ALUMINUM ASH RECOVERY SYSTEM

It is applied to the hot slag produced in the process of aluminum regenerative smelting and refining. It is suitable for the manufacturer with 300 kg ~ 2 T aluminum slag per time.

The recovery of aluminum can reach 80% ~ 90%.

Fully closed design, particle emission concentration ≤ 10mg / m3, meet the national environmental protection requirements. No hydraulic system, simple wiring, easy operation, no oil pipeline, easy maintenance.

Integrated automatic control, only need 1-2 people to operate, reduce the labor intensity of workers.

It can be operated in a complete set or used separately. Users can choose different equipment according to their own conditions.

Ash frying machine, ash cooler, screening machine, ash feeder, bucket elevator, dust collector, etc.

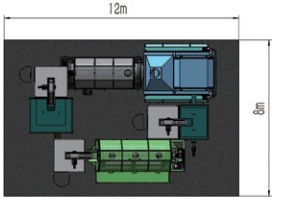

Floor area: 12m × 8m

Ash pan capacity: 0.6m3

Single processing capacity: 500 ± 100kg

Single processing time: 10 ± 3min

Air volume: 22000m3 / h

Recovery: 80% ~ 90%

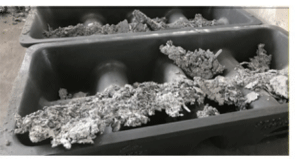

High efficiency slag press

High efficiency slag press

Unique design, can quickly cool the aluminum slag, quickly stop metal oxidation and burning. The metal recovery can reach 60-80%.

| Small Type

Dross capacity:250kg |

| Medium Type

Dross capacity:500kg |

| Large Type

Dross capacity:1000kg |

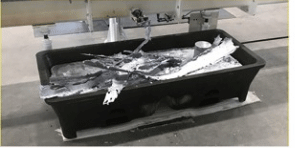

The aluminum slag pot and ingot mold produced by tuffcast are durable.

● Use site